How can I improve EBIT for my production site?

How can I improve EBIT for my production site?

How can I maximize product yield and plant efficiency?

How can I accommodate changing product demand and prices?

How can I reduce maintenance cost and improve plant reliability?

How can I cope with the gradual loss of experienced operators?

How can I build sustainable advanced automation and optimization capabilities into my plants?

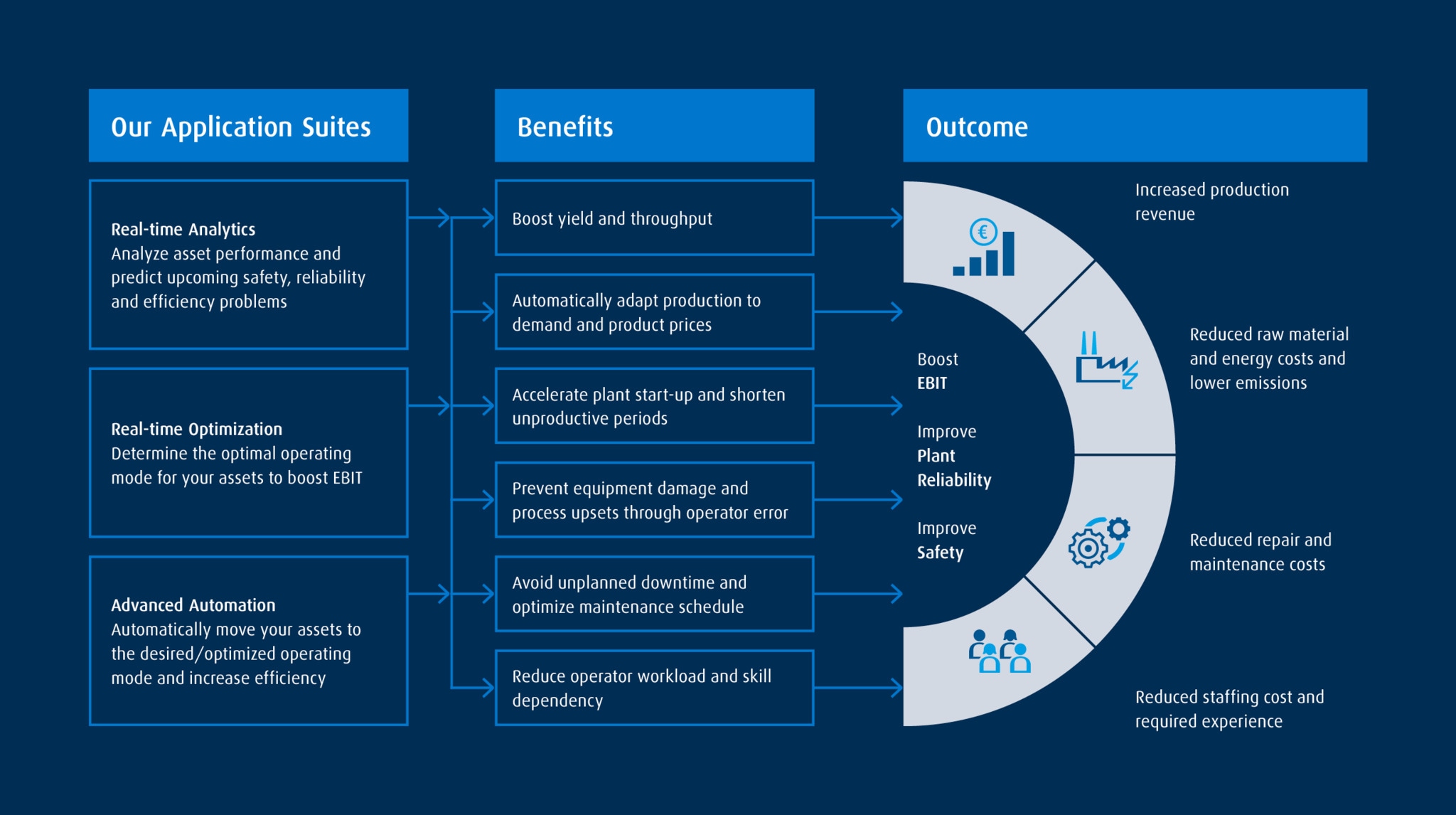

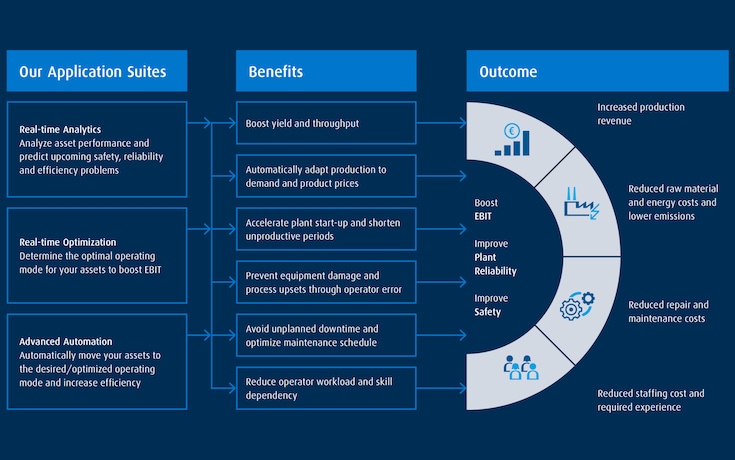

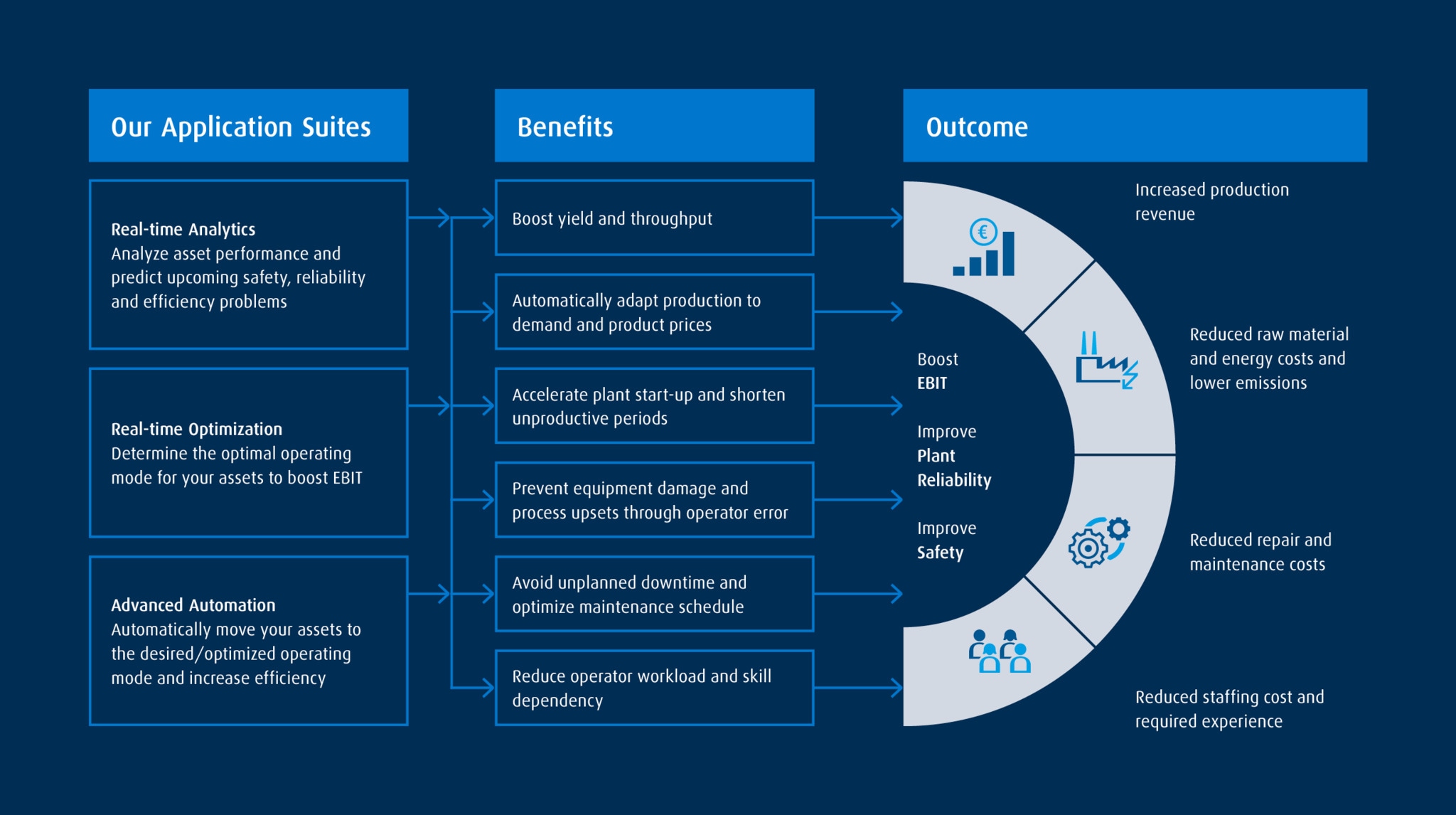

Improving EBIT for your process plants with AI-powered optimization and automation solutions

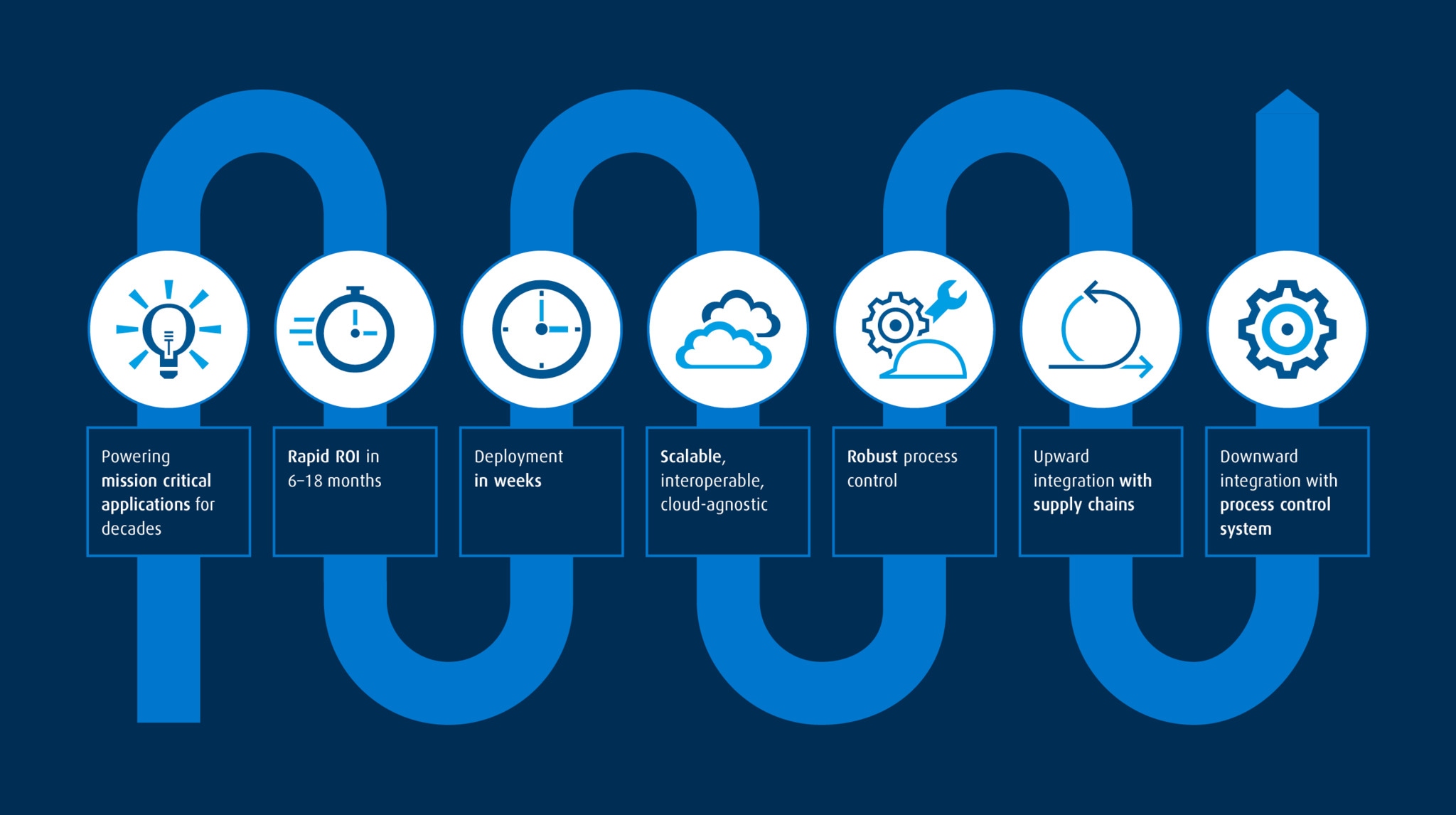

We build on the vast experience in operations and AI-powered advanced automation drawn from our own fleet of 1000 plants across 80+ countries to deliver fast improvements to the profitability and reliability of your assets while reducing your dependency on operator experience.

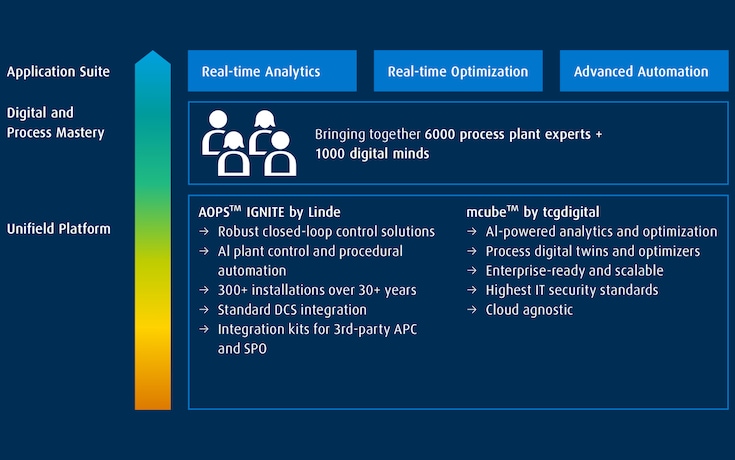

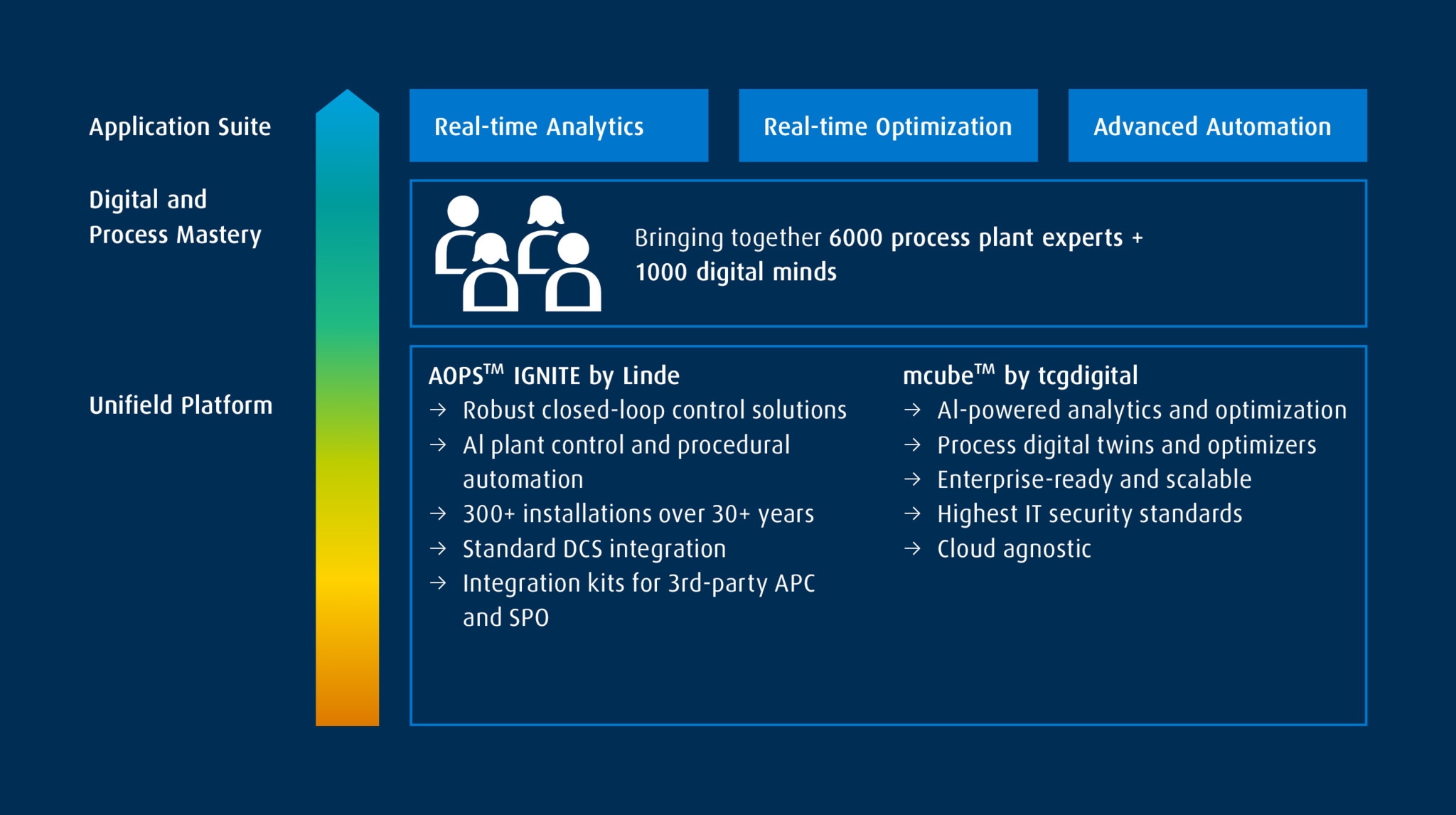

Tap into the synergies created by the alliance between our process plant experts and TCG Digital's AI innovators. Combining decades of expertise, our integrated application portfolio will help you maximize asset performance, drive EBIT, increase reliability and simplify operations.

Collect & Analyze

Simulate & Optimize

Operate & Manage

These solutions are complemented by our comprehensive consulting and remote services portfolio, giving you ongoing support and tailored guidance to help your plants achieve their full potential.

Developing the best solution and implementation plan to improve your operations.

Comprehensive operation, automation and staffing concepts, business cases, implementation plans and requirements (relative to licensors, EPC contactors, OEMs and main automation/electrical contractors) for your brownfield improvements and greenfield investments.

Custom-configured, real-time analytics, real-time optimization and advanced automation solutions.

Tailored to your pain points, our robust, mature proprietary AOPSTM -IGNITE Advanced automation platform and complementary AOPSTM applications for AI-powered advanced process control, procedural automation and real-time optimization can be seamlessly integrated with all DCS systems.

24/7 expert support to drive asset performance.

We deliver end-to-end software integration services to deploy, operate, maintain and optimize solutions that seamlessly integrate with your IT/OT systems. Our expert HYPE-R-CARE team provides 24/7 remote support services for real-time performance monitoring, predictive diagnostics, asset troubleshooting and operational improvements.

At LAOS, we empower our customers to overcome key productivity challenges by delivering robust, sustainable advanced automation and optimization solutions. Our unique expertise helps plants to adapt to fluctuating demand and pricing, reduce operating expenses, address the shortage of experienced operators, enhance reliability, and maximize product output and operational efficiency.

improvement in productivity, product yield and efficiency through real-time optimization and advanced automation

reduction in maintenance costs by avoiding unhealthy operating modes specifically during startup and production mode changes

improvement in plant availability by eliminating operator errors, predicting upcoming failures and providing troubleshooting support

reduction in operator workload by automating routine activities and replacing manual checks with intelligent sensor systems

implementation time

ROI due to value-adding solutions

Take a few seconds to access a world of inspiring content that will keep you at the cutting edge of industrial plant management.