Read how we have successfully designed and built some of the world's largest and most impressive baseload LNG plants.

LICOMTM extends our StarLNG product portfolio to better serve the evolving small-scale LNG market, which demands best-in-class efficiency, easy permitting, easy operation and standardization.

LICOM is the ideal answer to these needs. This dedicated solution is a small-scale unit for the cost-effective liquefaction of natural gas and - in particular - of renewable natural gases (RNGs). Compared with conventional gas expansion based processes, this compander-based process offers significant process efficiency gains and requires less equipment.

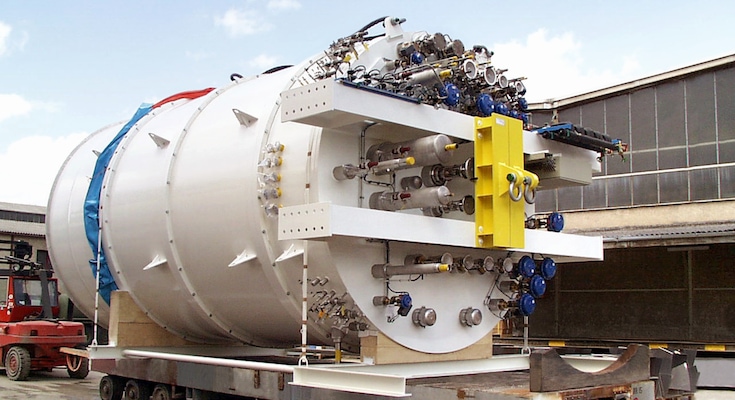

Depending on project-specific needs, our proprietary LICOM compander can be delivered as a core refrigeration unit or, for ease and speed of deployment, as a pre-fabricated solution. This fully packaged skid comes complete with aftercoolers, an oil system, control valves, silencers, safety valves, a programmable logic controller (PLC) and seal gas in a single-train configuration, covered by five frame sizes to suit your project needs. Liquefaction capacities range from 100 tons per day (tpd) to 1,650 tpd of LNG in a single-train configuration. LICOM comes in five frame sizes to suit individual project needs.

Design highlights of LICOM include a gas expansion based process leveraging our proprietary integrally geared machines (known as a compander). This new gas expansion process represents a significant breakthrough, enabling the liquefaction of pipeline or renewable natural gas with 10% - 15% higher process efficiency than conventional nitrogen expansion solutions. The result is a significant reduction in operational expenditure and greater sustainability. The pure nitrogen refrigeration cycle, offering hassle-free refrigerant makeup or import, ensures straightforward permitting and easy operation of the technology.

The integration of additional compression and expansion services, such as feed gas compression within the nitrogen boosters/expanders, is achieved using only one integrally geared machine (compander). This approach keeps the equipment count to a minimum, resulting in attractive capital expenditure and minimum plot space requirements.

Our LICOM plants meet the highest quality standards thanks to in-house design, manufacturing, assembly and testing of all key components. In addition, full control over the supply chain, from process design to delivery of key components, by one trusted supplier accelerates delivery times.

Complementing our refrigeration and liquefaction units, we also offer feed gas pretreatment for pipeline gas ("balanced biomethane") as well as upgrading and purification of biogas to genuine biomethane. In addition, our expertise includes LNG storage and loading, utilities, CO2 purification and liquefaction. Our scope of service covers the full spectrum - starting with prefabricated packaged units or skids just for refrigeration and liquefaction all the way up to full engineering, procurement and construction (EPC) responsibility for your project.

LIMUMTM is a core process within our StarLNG family. Designed for extremely efficient operations, it uses a single mixed refrigerant (SMR) cycle. This mixed refrigerant cycle typically uses four refrigerants: nitrogen, methane, ethylene or ethane (depending on availability) and butane. For capacities up to approx. 1,000 tons per day (tpd), the LIMUM process is typically equipped with plate-fin heat exchangers (PFHEs).

To support higher capacities extending up to around 3,000 tpd per train, LIMUM can also be supplied with our proprietary coil-wound heat exchangers (CWHEs). This can be an attractive solution for operators keen to avoid the potential operational complexity and added cost of multiple parallel blocks of PFHEs. SMR designs can offer substantial operating cost gains over gas expansion based technologies for applications with high annual operating hours near design load.

Similar to our LICOM concept, all LIMUM solutions rely on standardized machinery, equipment and instrumentation. Prefabricated modules can significantly accelerate on-site deployment while also reducing project complexity and schedule risks.

Our LIMUM process technology, combining the liquefaction and refrigeration units of an LNG plant, is available as part of a wider plant concept, typically consisting of natural gas pretreatment (sour gas removal and dehydration), utilities as well as LNG storage and loading.

When designing your LNG plant with our LIMUM process technology, the choice of heat exchanger will depend on your plant capacity and operational requirements.

Both our coil-wound and plate-fin models - in addition to leveraging the benefits of in-house design and the fabrication quality of our world-class LNG heat exchangers - offer their own distinctive advantages as outlined below.

Talk to one of our experts and discover how you can reduce your carbon footprint with our engineering innovations - today.

(PDF 3.0 MB)

(PDF 2.0 MB)

(PDF 2.0 MB)

Read how we have successfully designed and built some of the world's largest and most impressive baseload LNG plants.

Discover our tailored solutions for the recovery and liquefaction of valuable helium gas from natural gas streams.

Check out our nitrogen rejection units featuring tailored process technology to ensure highest efficiency and economics.

Build on our long-standing experience in the design, development and construction of plants to recover NGL and LPG.