More Information

Powering the Transition to Net Zero with Electric Cracking Technology

STARBRIDGE Academy

STARBRIDGE builds on years of collaborative innovation to deliver a breakthrough in high-temperature electric heating for steam cracking and other demanding applications. Based on resistive heating, the eFurnace replaces fossil fuel combustion with electricity, enabling continuous production with minimal CO2 emissions and seamless integration into existing infrastructure. Offering exceptional electrical efficiency, uniform heat profiles, and simple operation, the technology enhances performance while reducing direct emissions by more than 95%. Developed jointly by Linde, BASF, and SABIC, STARBRIDGE combines leading process, operational, and EPC expertise to accelerate the transition to scalable, low-carbon industrial heating. In regions with abundant low-carbon power, it further supports long-term cost stability by reducing exposure to fuel gas and CO2 infrastructure markets. Two complementary resistive-heating concepts — indirect and direct — have been fully developed and brought to commercial readiness.

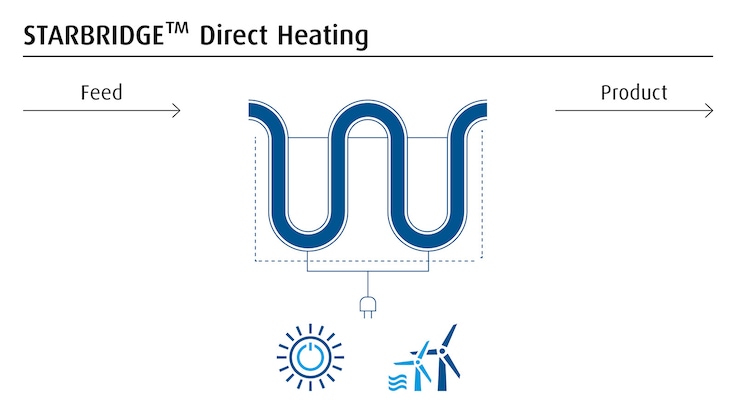

In the direct heating concept, electric current is applied directly to the process tubes, generating heat through Joule heating within the tube walls themselves. This removes intermediate heat-transfer steps and enables unique dynamic and control capabilities. The concept enables a compact design and delivers high efficiency through its inherently robust design, suitable for a large temperature range even beyond 900 °C. The proprietary configuration provides major advantages in scale, thermal efficiency, footprint, operational flexibility and lifetime, resulting in outstanding total cost of ownership. Typical applications include steam cracking, high-temperature gas heaters in the cement and steel sectors, and other gas-heating duties transitioning away from fuel-fired technologies.

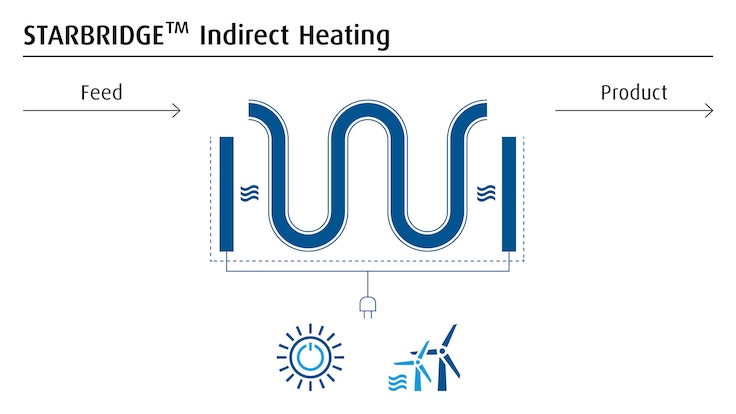

In the indirect heating concept, electricity is supplied to robust resistive heating elements located within the coilbox. These elements heat up and transfer energy mainly by radiation to the process coils, creating a configuration similar to a conventional radiant-box furnace, but with electric elements replacing burners. Designed for medium-high process temperatures of roughly 300–900 °C, this approach fills a technology gap where conventional electric heaters may be limited by scale, durability or maintainability. The electrically heated radiant-box setup provides stable, controllable heat delivery at elevated temperatures and is well suited for applications such as steam cracking, EDC furnaces, refinery heaters and other thermal units requiring efficient and reliable high-temperature operation.

Source: BASF SE

The industrial-scale demonstration of electric steam cracking represents a significant step forward in decarbonizing high-temperature operations. By validating both direct and indirect resistive-heating concepts under real commercial conditions, the project demonstrates that electric furnaces can reliably deliver high temperatures, precise control, and operational flexibility — without the CO2 emissions associated with fuel combustion. Experience gained from EPC and operation has enabled the development of mature, scalable eFurnace designs that integrate seamlessly into existing crackers and accommodate diverse feedstocks.

Beyond steam cracking, these concepts form a versatile foundation for broader industrial electrification, supporting high-temperature heating across multiple sectors. Commercial deployment is ready to accelerate, providing a practical, future-proof pathway to low-carbon electric operation.

Flexible Technology:

Environmental & Cost Advantages:

Performance & Reliability

Talk to one of our experts and discover how you can reduce your carbon footprint with our engineering innovations - today.