Adsorption-based Carbon Capture Solution

Introducing HISORP CC - The Ultimate Carbon Capture Technology Toolbox Paving the Way for a Sustainable Future!

Step into the Future with HISORP CC!

HISORP CC is a valuable tool in today's forward-looking carbon capture, utilization and storage (CCUS) strategies. It is suited to a wide range of carbon dioxide (CO2) sources, achieving CO2 capture rates above 95% and delivering the CO2 product ready for sequestration. Each HISORP CC plant is individually designed based on mature technologies best suited to meeting individual needs. Experience the future of your industry with HISORP CC and join us now to maximize your operations and take it to the next level.

Growing Importance of CCUS Technologies in Climate Mitigation

Global warming and climate change concerns are intensifying global efforts to reduce emissions of greenhouse gases such as CO2 into the atmosphere. To achieve net zero, large industrial emitters must decarbonize their operations. This involves capturing CO2 at the source and managing it through CCUS technologies, which include reusing the CO2 in other industrial processes to create valuable products or storing CO2 safely underground.

Industries with significant point sources of CO2 include cement, lime and electric power plants, iron and steel mills, chemical and petrochemical facilities. In addition, synthesis gases from the chemical industry and various processes in the oil and gas upstream sector are significant sources of CO2 emissions.

CCUS technologies play a strategic role in meeting today's carbon emission reduction targets. To reach global net zero within the coming decades, investments in CCUS projects will have to be stepped up significantly.

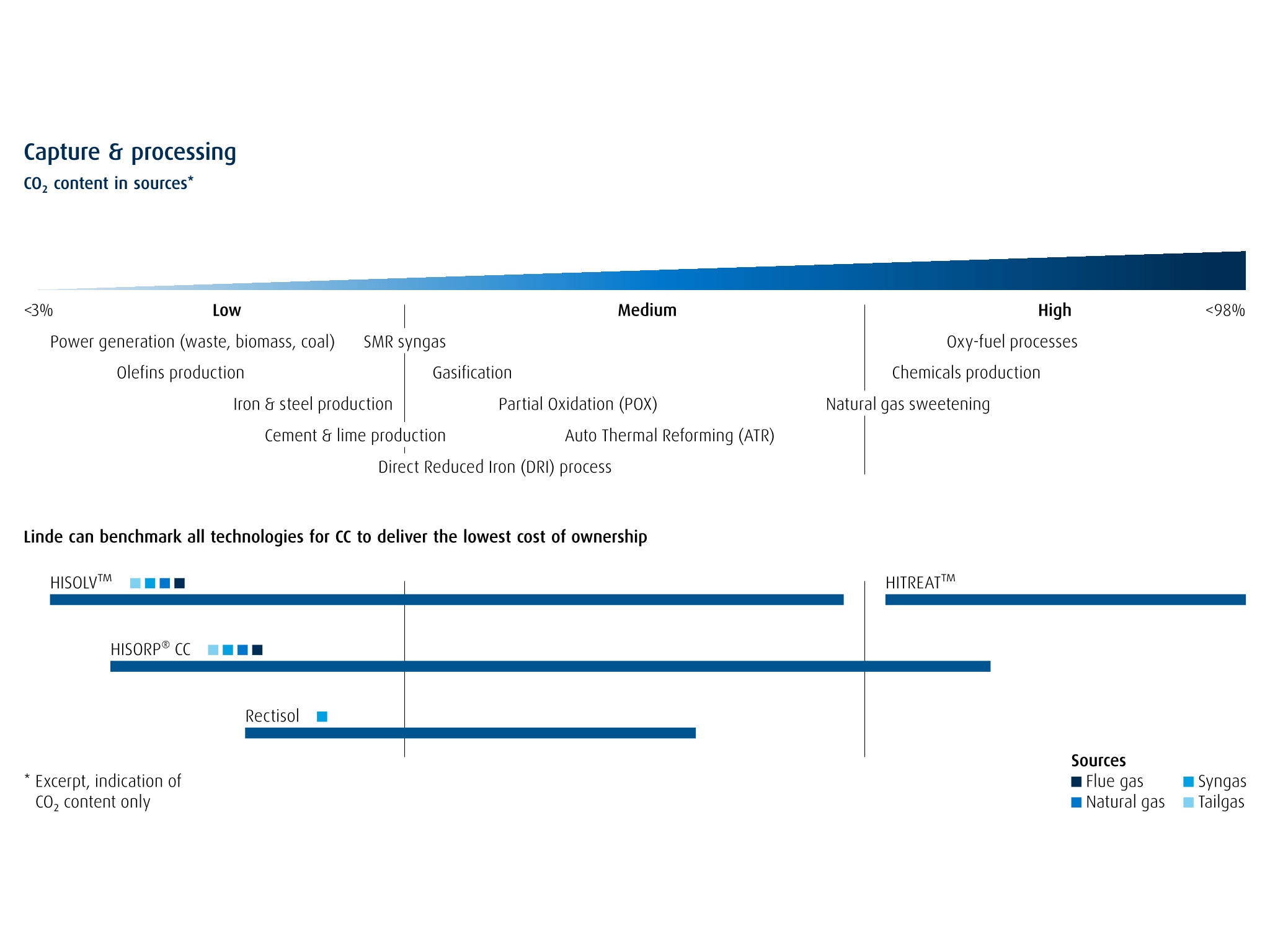

Delivering the Best Technological Solution

Our broad technology portfolio is suited to a large variety of carbon-emitters across a broad CO2 concentration envelope. Absorption-based technologies are typically preferred at the lower end of the concentration spectrum. For applications with higher CO2 concentrations - such as flue gas from cement production or process gases from blue hydrogen production units -our flexible HISORP CC offerings are often the solution of choice. At the higher end of the spectrum, CO2-rich streams from oxyfuel combustion and chemicals production can be easily captured and purified with our cryogenic technologies.

With over 40 years of experience in building carbon capture plants and flagship reference projects worldwide, we have the expertise and track record to cover source concentrations anywhere from below 10% to over 90% at various pressure levels and feed flows.

Our expert team can help you select the technology and configuration best suited to your capture and recovery targets.

This illustration gives an overview of Linde's tailored solutions for carbon capture. Depending on the CO2 source and concentration, different CC technologies have unique advantages. Complementing our adsorption-based HISORP CC technology described in detail on this page, we also offer Advanced amine wash solution (HISOLVTM), a Rectisol physical acid gas removal process and a cryogenic-based CO2 Processing Unit (HITREATTM).

HISORP CC in Focus: 99+% CO2 Capture Rates

HISORP CC is a sophisticated carbon capture toolbox that address the need for highly efficient capture and separation processes in various industries. This electrically driven technology is highly effective in capturing and purifying CO2 from a wide range of carbon sources, building on our extensive expertise and proven success in pressure swing adsorption (PSA), cryogenic separation, CO2 drying and compression.

The HISORP CC toolbox provides flexible and scalable solutions for diverse feed gas streams, covering all relevant industrial sizes and all purity levels. Each HISORP CC plant is individually designed to bring you the mature technologies best suited to meeting your individual needs.

HISORP CC is suitable for low-pressure sources, such as flue gases from combustion processes, for industries like cement, steel and power, and for hydrogen production by means of steam methane reforming (SMR). Additionally, it removes CO2 from sour gas sources throughout the oil and gas lifecycle and can be tailored for CO2 capture rates above 95%.

For high-pressure sources, particularly high-pressure synthesis gases in hydrogen production processes, HISORP CC effectively captures CO2 emissions from autothermal reformers, partial oxidation processes, steam methane reformers and gasification units. By integrating our advanced in-house adsorptive and cryogenic technologies, it achieves CO2 capture rates of 99+% while preserving the hydrogen product.

HISORP CC is based on a toolbox concept. It is an advanced, electrically driven carbon capture technology designed to efficiently capture and purify CO2 from diverse industrial gas streams. Leveraging our expertise in pressure swing adsorption (PSA), cryogenic separation, drying and compression, HISORP CC offers flexible solutions for different deployment scenarios including low-carbon hydrogen production, the removal of CO2 from flue gases and carbon capture from sour gas sources. It achieves high CO2 capture rates and supports multiple product forms (gaseous, liquid and supercritical).

HISORP CC Features

Many key features make HISORP CC a superior choice for CO2 capture in various industries:

- 100% electrically driven: Operates entirely on electrical power with no steam required.

- Flexible toolbox concept: Can be tailored to your needs with flexibility in size and scale, ranging from around 100 to more than 10,000 tpd of CO2.

- Adaptable CO2 product requirements: HISORP CC can be adjusted to various CO2 product requirements (gaseous, liquid, supercritical) and purity grades - extending from industrial to food and beverage grade.

- Packaged unit design: Pre-manufactured and workshop-tested modules mean transportation, erection and commissioning effort are minimal.

- Chemical-free operation: Lower OPEX for consumables and lower environmental impact as chemical washing agents are not required, which means no effort for handling, makeup or disposal of degradation products and no emissions from chemical agents.

- Cost effectiveness: Low costs overall through CAPEX and OPEX savings.

- Ideal for retrofits: Optimum solution also for plant retrofits due to high level of integration flexibility.

Selected Flagship Projects

HISORP CC powers ADNOC's Hail and Ghasha project

We have partnered with NEXTCHEM to supply carbon capture technology for ADNOC's Hail and Ghasha project, demonstrating HISORP CC's advanced capabilities.

| Location: |

United Arab Emirates |

| Focus: |

Oil & Gas Upstream |

| Capacity: |

1.5 Mta CO2 |

HISORP CC Supplies Clean H2 to Dow's Path2Zero Project

We have signed a long-term agreement to supply clean hydrogen to Dow's Path2Zero Project in Canada, investing over $2 billion in a new facility. Our new on-site complex in Alberta will use autothermal reforming and HISORP CC carbon capture technology to produce clean hydrogen, capturing over 2 million metric tons of CO2 annually. On completion in 2028, it will be the largest clean hydrogen production facility in Canada and one of the largest globally. In this project, our largest single investment, we will support Dow's net-zero emissions ethylene cracker as well as other industrial customers seeking to decarbonize their operations. It will be the world's largest demonstration of decarbonizing ethylene cracker operations through the use of low-carbon hydrogen as a fuel source.

| Location: |

Fort Saskatchewan, Canada |

| Focus: |

Petrochemistry |

| Capacity: |

> 2Mta CO2 |