Deep Dive

More details are available here

EDHOX™ Technology Brochure

Article in Hydrocarbon Processing

Podcast "The Main Column"

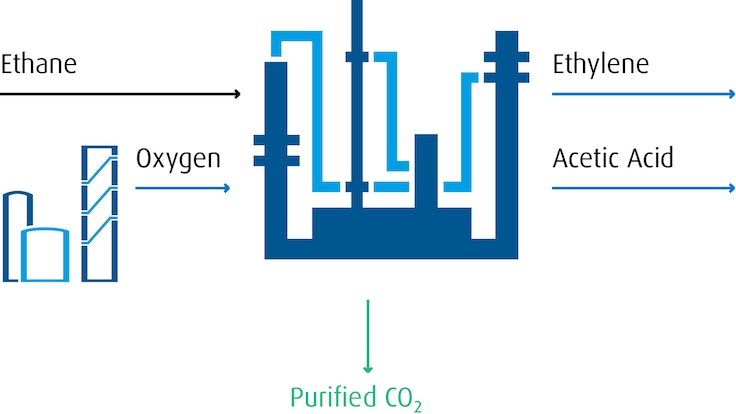

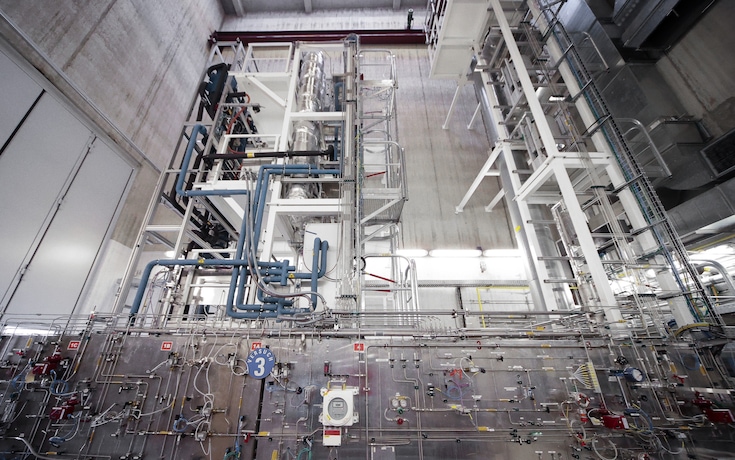

EDHOX is an on-purpose catalytic technology that converts ethane into ethylene and acetic acid in a multi-tubular reactor. A recently developed mixed metal catalyst is placed inside the reactor tube. This allows the dehydrogenation reaction to take place under mild conditions. It is a safe, reliable exothermic oxidative process that requires less energy than current state-of-the-art technologies.

An EDHOX plant includes a reaction section and a separation/purification section that provides downstream processes directly with ethylene and acetic acid. Unconverted ethane is also separated and is internally recycled back to the reactor. The combined ethylene and acetic acid yield is notably high, with overall selectivity above 93%. In addition, this oxidative dehydrogenation process recovers the carbon dioxide (CO2) produced as a pure by-product (for carbon capture, utilization or storage, CCUS).

Our EDHOX technology is designed to overcome the energy intensity challenges involved in conventional paths to light olefins such as ethylene. Steam cracking, for example, requires furnace process temperatures of up to 870°C. Based on the oxidative dehydrogenation of ethane, EDHOX operates at temperatures in the range between 300°C and 400°C, reducing investment and ethylene production costs. Furthermore, this high-performance solution offers the potential to significantly reduce carbon emissions compared with conventional ethane steam cracking technology.

EDHOX is the superior route for ethylene producers and is the ideal choice for processes requiring both ethylene and acetic acid, such as VAM (vinyl acetate monomer), EVA (ethylene vinyl acetate) copolymer, and PVOH (polyvinyl alcohol) products, PET (polyethylene terephthalate), ethyl acetate and similar derivatives.

Environmental Impact:

Energy Efficiency:

Catalyst and Reactor Design:

Financial Impact:

Talk to one of our experts and discover how you can reduce your carbon footprint with our engineering initiatives - today.