- Location: Jurong Island, Singapore

- Focus: Supply of H2 and syngas to ExxonMobil's integrated manufacturing complex

- Scope: Engineering, procurement, construction (EPC) for a new facility for H2 and CO production from heavy residues via gasification

- Plant design: Large air separation unit, gasification unit, Rectisol wash unit, sour CO shift unit, PSA unit and sulfur recovery unit

- Start-up: 2024

Benefit from Our Vast Expertise in CO and Syngas Plants

Syngas (short for synthesis gas) is a mixture of carbon monoxide (CO) and hydrogen (H2). This mix and its components are widely used in the chemical industry to produce synthetic fuels, methanol and ammonia. This gas mix also plays a crucial role in processes like Fischer-Tropsch synthesis, where it is converted into liquid hydrocarbons for fuel and lubricant applications. Additionally, syngas can be used to generate electricity and as a reducing agent in metallurgical processes.

CO and syngas plants require the same process steps: syngas generation, gas conditioning and gas purification. A leader in this business segment, we have built and delivered more than 100 plants worldwide for the production of syngas and the same number of coldboxes for the recovery of CO. Regardless of your feedstock and concentration range, we can help you achieve first-class results with your H2/CO project.

Our Syngas Offering

Syngas is produced by steam reforming or partial oxidation of hydrocarbons. It can also be produced by combining the steam reforming and partial oxidation (POX) processes (tandem reforming).

To meet individual capacity requirements, our syngas plants scale from 1,000 normal cubic meters an hour (Nm3/h) to over 2 million Nm3/h. Our highly flexible design concept means you can combine different processes to achieve your individual process specifications - whether that be a specific H2/CO ratio (by means of a CO conversion shift) and/or the separation of H2/CO.

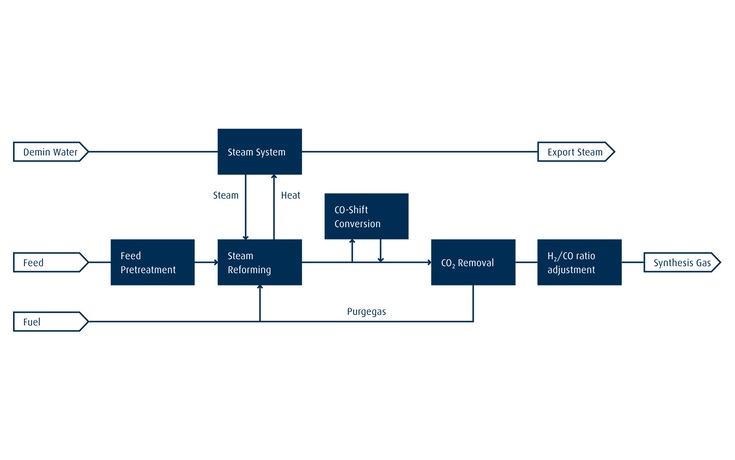

Process Flow for Light Hydrocarbons

Light hydrocarbon feedstocks like natural gas, liquid gas and naphtha are generally converted to a raw synthesis gas by means of catalytic steam reforming. This H2/CO mix is then further processed depending on the desired final products.

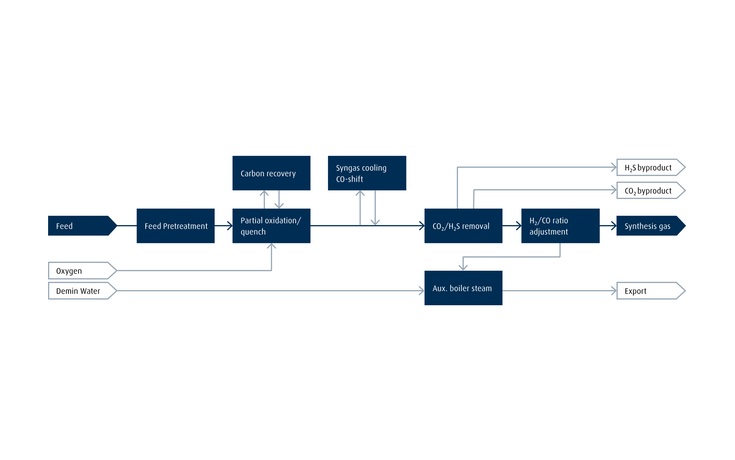

Generating Syngas from Heavier Feedstocks

In the case of heavy feedstocks like residual oil, the raw gas is generated by partially combusting the feedstock with oxygen in a non-catalytic partial oxidation reaction. This raw gas is then conditioned through additional process steps such as CO conversion, and purified into a marketable commodity by removing the sour gas components with our Rectisol wash solution and separating the H2 and CO by means of membrane technology.

Long-term Supply Agreement with ExxonMobil for H2 and CO

Our CO Offering

Our cryogenic gas separation processes can deliver all CO purity grades up to 99.99 vol.% while maintaining high recovery rates at low energy consumption. Plant capacities scale from 100 Nm3/h to over 65,000 Nm3/h. By converting hydrocarbon feedstocks and mixing them with H2, we can provide mixture ratios that meet your individual needs to support the production of acetic acid, polyurethane, polycarbonate, formic acid or phosgene.

We specialize in two different cryogenic separation processes for H2/CO/methane gas mixtures: condensation and methane washing. Here at Linde, we understand that there is no "one size fits all" answer to selecting and integrating the right cryogenic separation process. Our experts would be delighted to advise on the setup best suited to your individual needs. We have multiple references for both plant technologies.